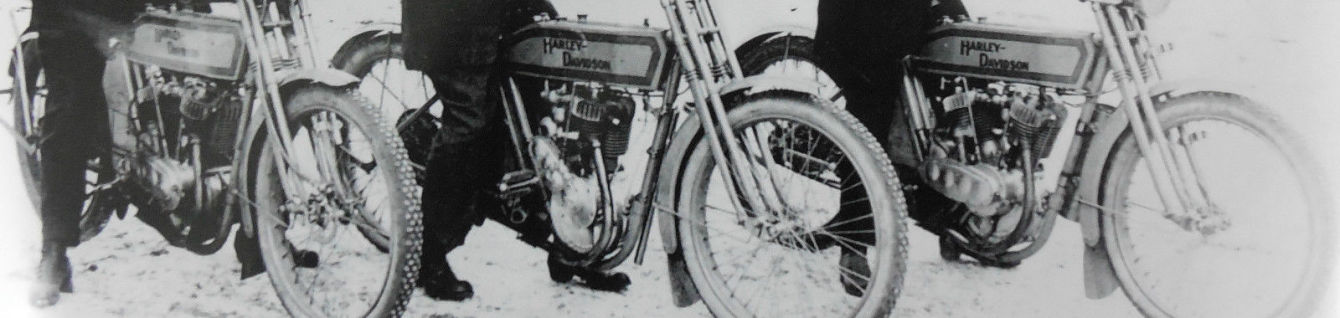

1910 motor work.

After months of work going through most parts of the machine we finally got her running, and running fairly well. There were still some issues to resolve but they would have been attended to over time. However, the seal of the bronze bush in the left side crank case was installed such that when the motor was run it just oozed oil.

Up to that point the only thing we hadn’t done was split the motor cases; so we did and found that the bush was OK. Machining the case and installing an oil seal made a big improvement.

There was a new piston and connecting rod inside but with no oil ring on the piston and no oil feed to the small end bearing. The exhaust valve also needed a little work in the seating department and we made a new valve lifter. She starts and runs a lot better now.