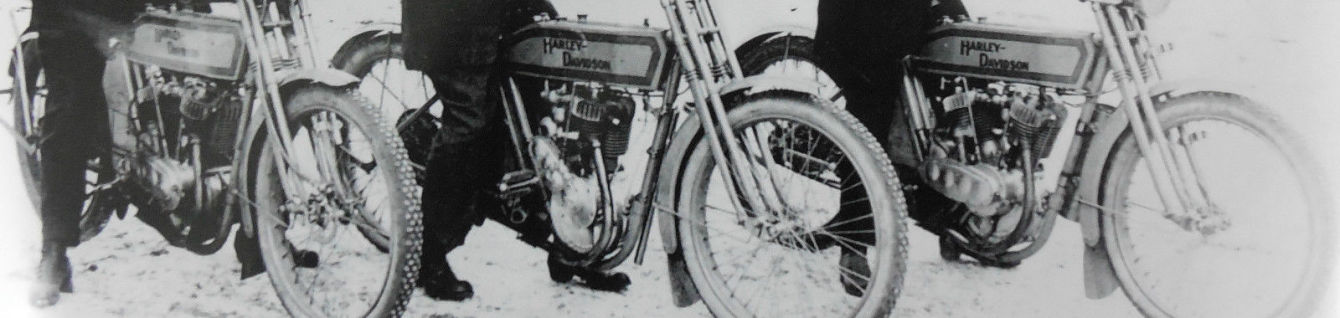

Timing, timing,timing.

The 9B seemed to be lacking power recently so we decided to double check all the timing; that is for the exhaust and inlet valves, and the ignition.

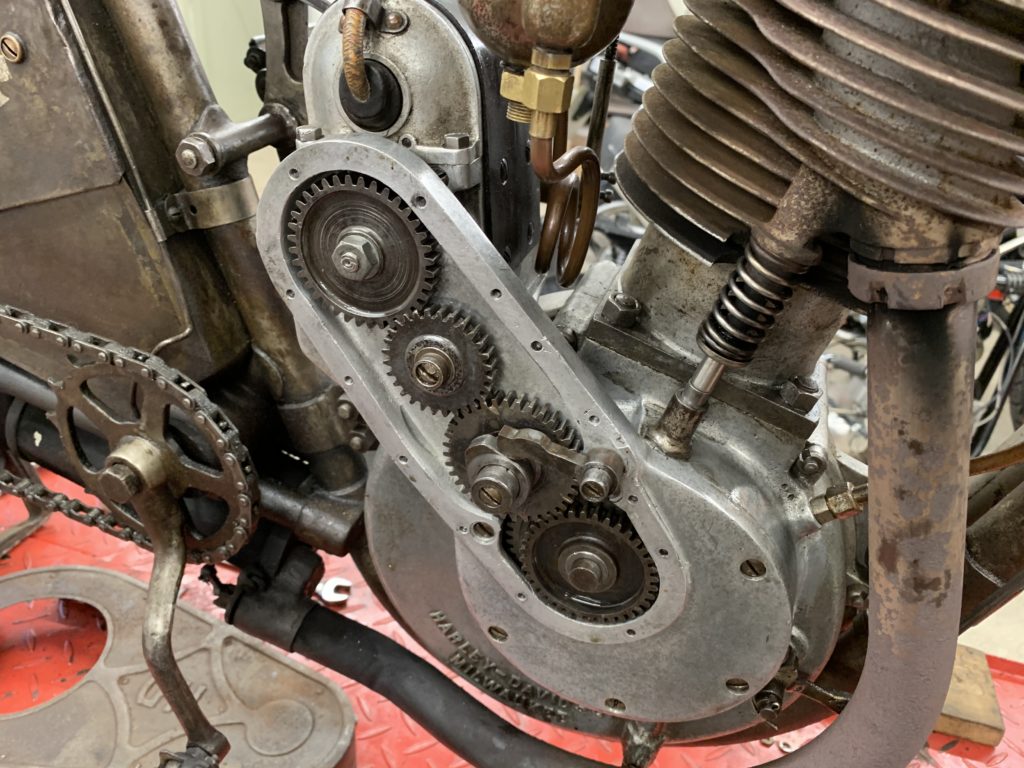

First, remove the timing cover and then the magneto perch, complete with magneto. The exhaust valve operates via a cam on (behind) the larger gear wheel which is not visible when the magneto cover is still in place. The valve closes when the piston is 1/32” to 3/32” after top dead centre. The piston is visible when you remove the inlet valve tower.

With the exhaust valve done, the next gear wheel operates the inlet valve. Refit the cover and the pushrod to set the timing such that the valve opens 3/16” before the piston reaches TDC.

Then refit the intermediate and the magneto gears. The ignition should be set so that the breaker points are just separating at 3/16” – 1/4” before TDC on the compression stroke. Then the inlet pushrod and the timing cover need to be refitted, as well as the inlet valve tower. Job done, we now need to wait for some decent weather to do a test run.

A couple of notes; first we removed the front chain cover and turned the motor by hand with a wrench rather than by turning the rear wheel, and second TDC. The book says the way to determine TDC is to remove the motor from the frame and check the piston by looking through the top motor plug. Well that’s a lot of extra work so we went in through the inlet valve tower……they say not to do it that way!